Lubrication 101: Choosing the Right Oil for Your Phonograph

Restoring antique phonographs often involves meticulous cleaning, parts replacement, and, crucially, proper lubrication. Incorrect lubrication can lead to increased wear, noise, and even damage to delicate mechanisms. This guide will break down the basics of lubrication, focusing on the types of oils suitable for your phonograph and how to select the right one for different components.

Why Lubrication Matters

Phonographs, especially those from the early 20th century, rely on precise mechanical movements. Friction between moving parts generates heat and wear. Proper lubrication reduces friction, minimizes wear, prevents seizing, and contributes to a quieter, more enjoyable listening experience. The original lubricants used in these machines were often based on animal fats or mineral oils that degrade over time, requiring replacement.

Types of Lubricating Oils – What to Consider

Not all oils are created equal. Here’s a breakdown of common choices and their suitability for phonograph restoration:

- Mineral Oil: A readily available and inexpensive option. It’s generally suitable for lighter lubrication of gears and levers. However, it can be prone to thickening in colder temperatures and thinning in warmer temperatures. Choose a light viscosity.

- Synthetic Oils: Offer superior performance compared to mineral oils. They have a wider operating temperature range, offer better lubrication, and are more resistant to degradation. Synthetic oils are often preferred for critical components like the motor and escapement.

- Clock Oil: Specifically formulated for delicate clock mechanisms, clock oil is an excellent choice for phonographs. It’s typically a lightweight, synthetic oil with excellent viscosity and lubricity. It's considered a 'safe' option for most applications.

- Silicone Oil: While offering some benefits, silicone oils can sometimes attract dust and debris, potentially causing issues in delicate mechanisms. It’s generally *not* recommended for most phonograph restoration projects unless specifically called for in the original documentation.

- Graphite Lubricants: These are often dry lubricants, meaning they don't rely on a liquid carrier. Graphite can be useful for specific points of contact that require minimal oil, but it's generally not a replacement for conventional oil.

Specific Component Recommendations

Here’s a guide to recommended oils for common phonograph components:

- Motor Bearings: Clock oil or a lightweight synthetic oil are ideal. These bearings experience significant load and require consistent lubrication.

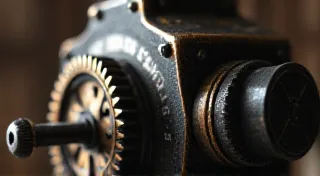

- Gears: A light mineral oil or clock oil is typically sufficient.

- Escapement: Clock oil is highly recommended for the escapement mechanism due to its precision and low viscosity.

- Tone Arm Pivot: A very light clock oil or a specialized tone arm oil is best, applied sparingly. Too much oil here can attract dust and affect tracking accuracy.

- Spindle: A very light oil, like clock oil, can reduce friction and noise.

- Needle Bearing/Stylus Lubrication: Do NOT lubricate the stylus directly. Some restorers *may* apply a *tiny* amount of specialized stylus lubricant to the cantilever, but this is an advanced technique and should be approached with caution.

Application Tips

Less is more when it comes to lubricating phonographs. Excessive oil attracts dust, can gum up mechanisms, and can even damage parts. Use an oiler or a fine brush to apply a small, precise amount of oil to each component. Wipe away any excess oil immediately.

Safety Precautions

Always work in a well-ventilated area when applying oils. Some oils can be flammable, so avoid open flames. Consult the phonograph’s original documentation or a trusted resource for specific lubrication recommendations.